2 INCH X 72 INCH GRINDING BELTS EXPLAINED:

In this article we will go over what the different types of 2" x 72" sanding belts are and what they are used for. We will guide you through the process to help you understand what a ceramic belt, zirconia belt, aluminum oxide & structured abrasive belts are used for in knife making or metal fabricating and help you choose which is the right abrasive for you. Whether you are a knife maker, welder or general metal fabricator, this guide is for you and will help you in learning & understanding what these materials are.

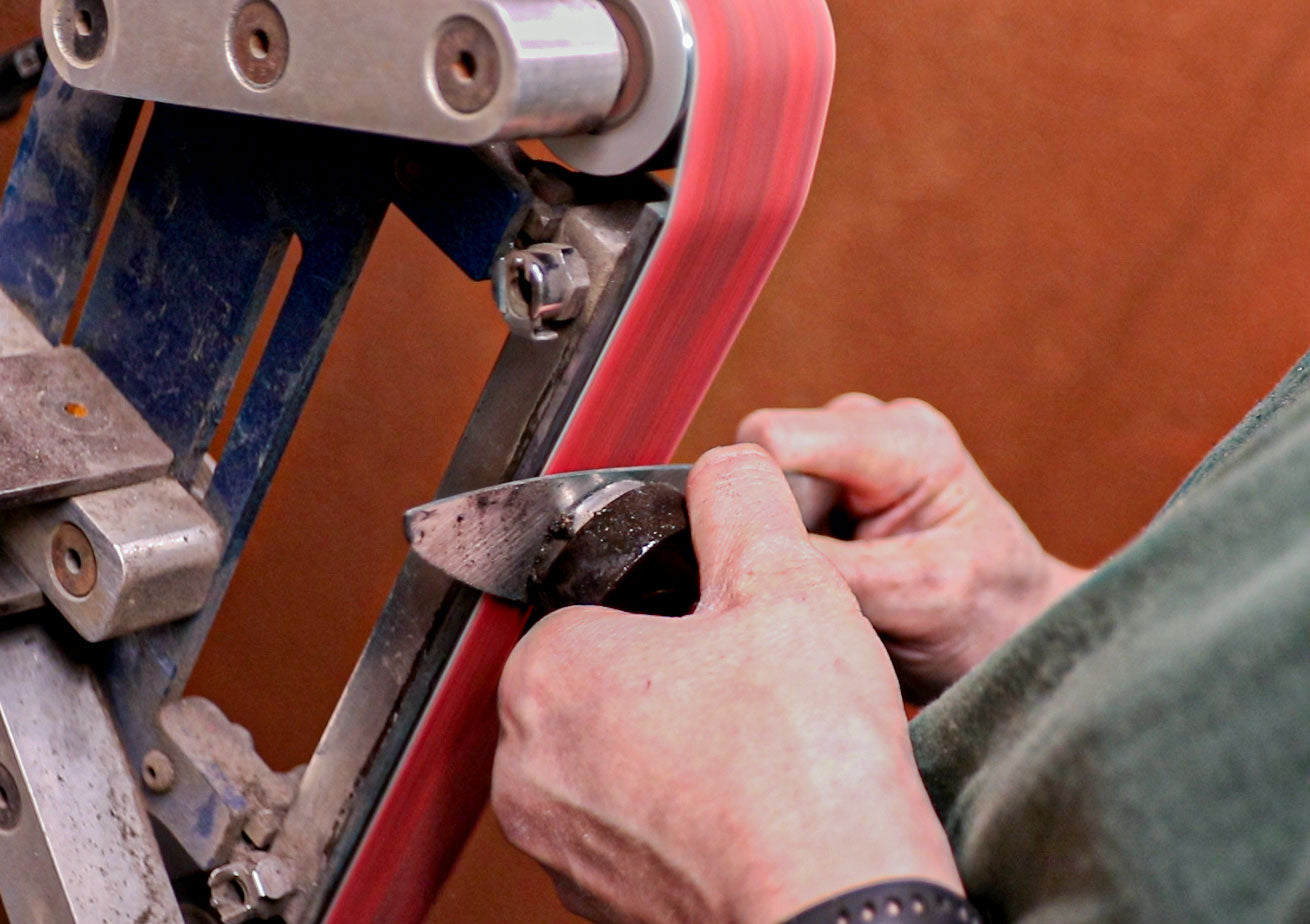

CERAMIC SANDING BELTS FOR KNIFE MAKING AND METAL FABRICATION

Ceramic sanding belts are the most dense, long lasting abrasive grain you can get in a sanding belt other than say a diamond belt....yes i said diamond....but you can imagine how expensive those are! Anyway, so 2" x 72" ceramic sanding belts are usually identifiable by their color which are most commonly RED or ORANGE but can also be yellow or purple depending on the manufacturer. Ceramic belts are made using a polyester backing which means you can run them WET or DRY. Additionally they are usually made on a stiff Y-weight backing that give them the strength and durability to hold together in high pressure situations.

While ceramic sanding belts can be more expensive than zirconia or aluminum oxide belts, they are FAR superior in their grindability, longevity, stock removal and price if you were to run a part by part comparison. To give you some insight, 2" x 72" ceramic sanding belts are the #1 most common sanding belt we sell at Combat Abrasive by far! Ceramic sanding belts are versatile and can be used to sand steel, stainless steel & handle material made of wood, copper, brass, or plastic such as G-10.

Ceramic sanding belts are only offered in grits 24 through 120 grit and we have a special ceramic J-flex belt available in 220 grit. The reason why ceramics are only offered in this grit range is because ceramic grains are very tough to break down hits a point of not providing the best finish once you go past this grit other than special cases where a blend of aluminum oxide and ceramic is used.

You typically will use the coarsest grits such as 24 grit, 36 grit or 40 grit for blade shaping and profiling stages where you would be removing the most amount of material. These grits are where you will absolutely get the biggest bang for your buck as stock removal generates a ton of heat, uses a lot of pressure and hogs away a lot of material. While you do not need to use all three of these grits, using them in sequence will save you the life of each belt as each finer grit will utilize less life because you arent working as hard to get out line grains from skipping grits.

BEST SANDING BELTS FOR HEAVY STOCK REMOVAL: SHREDDER BELTS BY COMBAT ABRASIVES

Rule of thumb for ceramic sanding belts:

Ceramic will last 3X longer than zirconia belts

Ceramic will last 10X longer than aluminum oxide sanding belts

ZIRCONIA SANDING BELTS FOR STOCK REMOVAL ON METAL AND WOOD

Zirconia belts are long life sanding belts that are made for aluminum, steel, stainless steel and even woods. Zirconia, while a long life belt are the older technology of belt before the ceramic sanding belt was developed. While you sometimes see them being used in knife making, they are generally used by the old school knife makers that like the low price and long life of the belts and didn't care to even try the longer life ceramic belts we mentioned above. Zirconia belts are made on a polyester Y-weight backing that allow them to be ran WET or DRY and give them extra durability for heavy grinding applications.

Zirconia belts are available only in the coarse grits such as 36 grit, 40 grit, 60 grit, 80 grit & 120 grits. This is because the zirconia grain does not break down very well when it gets past 120 grit and thus is counter intuitive to achieving a fine finish in your work piece.

We do find that some knife makers that are accustomed to ceramic belts will sometimes buy zirconia belts to heavy stock removal on handle materials that are soft and will tend to clog up the belts such as soft wood handle materials. It is important to note that you do not need to worry about clogging on hard wood materials and it is in fact better to go with a ceramic when sanding hard woods like maple burl etc.

To summarize, zirconia belts are a great option if you are doing heavy stock removal and want to spend the least money possible because you are a beginner and maybe don't have the money for ceramic.

Zirconia belts will last about 2-3X longer than aluminum oxide sanding belts

ALUMINUM OXIDE SANDING BELTS FOR KNIFE MAKING AND METAL FABRICATION

2" x 72 "Aluminum oxide sanding belts are some of the most common sanding belts used in knife making and metal fabrication due to their wide availability in grit range ( 36 grit to 800 grit ) and affordability. These belts range anywhere from $ 1.50 to $ 2.50 and provide a great finish and decent life for pretty much all grits. The main thing that sets these belts apart from their zirconia or ceramic counter parts however is that they are available in the finer grits from 120 to as high as 800 grit which can pretty much give you any type of finish you desire.

Aluminum Oxide sanding belts are offered in X-weight or J-flex backings. It is very important for all knife makers to know the difference between these two as J-flexes are very handy for handle work and putting an edge on a blade using the slack of the belt!

X-Weight Aluminum Oxide Sanding belts for Knife Making

2" x 72" X-weight Aluminum oxide belts are some of the most common and versatile belts you can buy and are incredibly affordable. These belts are not that rigid but are slightly more flexible than a zirconia or ceramic sanding belt. These are typically used to sand everything including the handle, bevel, plunge ines, bolster, tang, scales etc. You can literally sand everything on a knife using an aluminum oxide X-weight belt BUT a J-flex is very useful for contour sanding which we will go over next. X-weight belts are offered in the following grits: 36 grit, 60 grit, 80 grit, 120 grit, 150 grit, 180 grit, 220 grit, 320 grit, 400 grit, 600 grit & 800 grit.

J-flex Aluminum Oxide Sanding belts for Knife Making

2" x 72" J-flex Aluminum oxide sanding belts are primarily used when SLACK belt sanding handles where you are fine finishing or slack belt sanding the edges of the blade where you have more push to work into the edges. J-flex belts typically don't last quite as long as A/O X-weight belts because of their softer backing so it is recommended to purchase the J-flex belts and use them for specific purposes. J-flex belts are also the same material used for making 1" x 72" scalloped edge belts which are used specifically for sanding curvy handles where a 2 x 72" is either too big or will cut/slit into the handle materials. J-flex belts belts can be used on stainless steel, steel, aluminum, wood, epoxy, or plastics such as G10. J-flex belts are typically only for fine finish as well so they are only available in grits 120, 220, 320, 400 & 600 grits. Our combat abrasives J-flex material stands out from the rest due to its combination of superior life and flexibility over other retailers.

STRUCTURED SANDING BELTS FOR KNIFE MAKING ( TRIZACT TYPE )

Structured abrasives were popularized by 3M for their revolutionary Trizact material which was made famous for a GORGEOUS fine finish on metal. Our version of this 2" x 72" belt is called out by its name Structured Abrasive . These belts are made using flexible J-weight backing using a proprietary aluminum oxide structured grain

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.