HOW TO CHOOSE THE RIGHT SANDING BELTS FOR BEGINNING KNIFE MAKERS:

When it comes to starting out knifemaking the supplies you use are absolutely critical to a producing a functional knife or collectors item that you or your customers will feel proud to own. This guide it break down what you don't know and put you on the path of discovery so you master the craft. This will cover everything from abrasives to the right people to watch to common equipment used in knifemaking.

VIDEO CONTENT:

We highly recommend checking out our youtube or Walter Sorrells' Youtube channel for visually informative information how to make all types of knives from start to finish. Walter Sorrells is THE BEST and MOST INFORMATIONAL youtuber in the knifemaking community BAR NONE! The reason why we love him is because he is a knife maker by trade and used to write books, so he thoroughly plans and writes out his content to give you ever nugget of information possible to help you along your knife making journey.

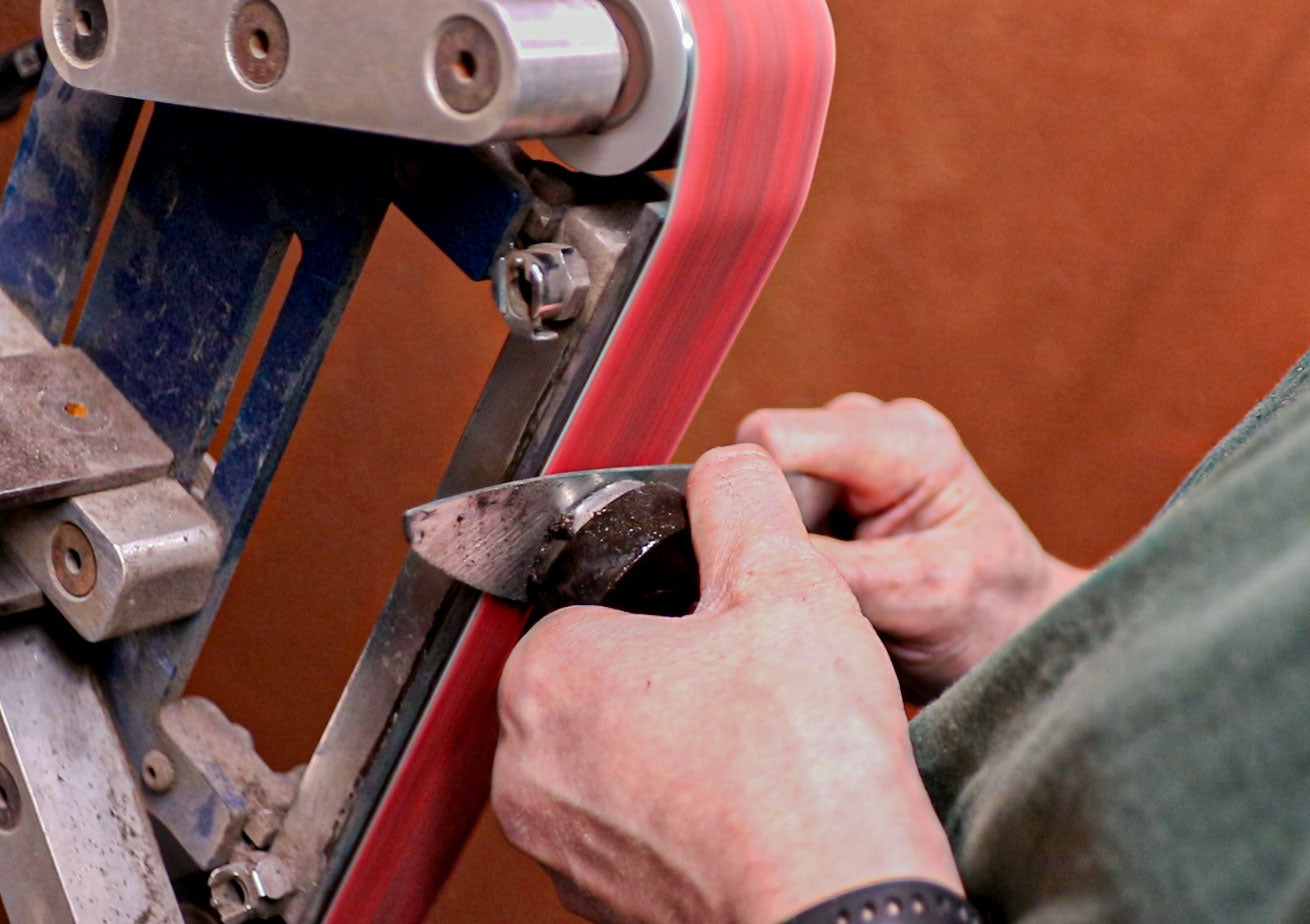

EQUIPMENT AND THINGS YOU NEED TO START OUT:

BEGINNER BELT SANDER

First off, you are going to need a 1" x 30" belt sander if you want to get started knifemaking for the most economical price. To make sure you first like the hobby or have some inherent skill we first recommend you get set up with a cost effective belt sander in combination with our 1" x 30" starter kit which has a fantastic mix of all the different types of belts you could want for almost any finish.

The #1 best belt sander for a beginning knife maker is the WEN 1" x 30" for the money because it's affordable, durage and also has a disc sander in the same machine which can be of tremendous use when bevel grinding or sanding other parts of your knife.

BEST BELT SANDER FOR BEGINNING KNIFE MAKERS: https://amzn.to/3kND0oP

SANDING BELTS FOR YOUR 1" X 30" BELT SANDER

This is our specialty here at Combat Abrasives. We developed our 1" x 30" sanding belt kit to have everything you need to get started as a knife maker. We include ceramic sanding belts and aluminum oxide sanding belts that are easy to use, affordable and LONG LIFE. You literally cannot go wrong with our 1 x 30 kit because it has everything from stock removal ( 60 GRIT & 120 GRIT) ) to fine finish ( 150 TO 800 GRIT ) which is an amazing value. With this kit you can do stock removal, bevel grinding, handle sanding & shaping, and any other type of sanding needed to complete a custom knife.

Here is everything in the kit:

- Three (3) 1" x 30" 60 Grit Ceramic Shredder Belts

- Three (3) 1" x 30" 120 Grit Ceramic Shredder Belts

- Five (5) 1" x 30" 150 Grit Aluminum Oxide X-Weight Belts

- Five (5) 1" x 30" 180 Grit Aluminum Oxide X-Weight Belts

- Five (5) 1" x 30" 220 Grit Aluminum Oxide X-Weight Belts

- Five (5) 1" x 30" 320 Grit Aluminum Oxide X-Weight Belts

- Five (5) 1" x 30" 400 Grit Aluminum Oxide X-Weight Belts

- Four (4) 1" x 30" 600 Grit Aluminum Oxide X-Weight Belts

- Four (4) 1" x 30" 800 Grit Aluminum Oxide X-Weight Belts

BEST STARTER KNIFE MAKING BELT PACK: 1" X 30 BELT STARTER KIT

BEST STEEL YOU CAN GET

The steel you use when knife making is incredibly important and we dont recommend skimping on your steel when it comes to prices and quality. There are some quality steels for almost every type we recommend when starting out knifemaking. The easiest steel BY FAR to start out with is 1084 steel or 1095 steel. Both 1095 and 1084 respectively are high in carbon, easy to heat treat and hold their edge better than almost all steel's making it a fantastic beginner steel.

BEST 1084 STEEL:https://amzn.to/3iGj5p9

BEST 1095 STEEL: https://amzn.to/3iEbVSv

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.